The corona crisis poses great challenges for companies, outpatient clinics, hospitals, retirement homes, social institutions and doctors around the world. In particular, hygiene and disinfection are vital. Peter Kenkel GmbH and meeco AG now provide fast, flexible and, above all, energy self-sufficient help. The two companies developed the mobile disinfection container, which can be quickly and easily set up and operated independently in front of hospitals, nursing homes, other social facilities, office buildings or on company premises.

What is special about it: The container, consisting of two separate disinfection areas and a hygiene lock, is operated with the help of high-performance solar modules, the energy management system and integrated energy storage for uninterrupted function. Thanks to the energy management system , the unique disinfection container can be operated independently and can therefore be set up and used anywhere, even in areas without any infrastructure or in the event of total infrastructure failure.

A mobile, flexible and variable solution

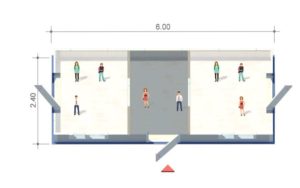

The mobile disinfection container enables eight people to disinfect the whole body at the same time. The room system consists of two separate disinfection areas, each for four people, and a hygiene lock. Container is also variable: five different container variants enable, among other things, contactless examination via a glove system for taking samples (e.g. saliva), a pass-through solution for whole-body disinfection in the form of a disinfection lock, and disinfection of parcel or other goods on a continuous conveyor belt.

The mobile disinfection container – how it works

After entering the container, the container users reach the hygiene lock and can go to the disinfection area from there. At the push of a button or automatically, spray mist disinfection is triggered in this room, which disinfects users within 30 to 40 seconds. This processes almost every water-based disinfectant. In the event of personal contact, make sure that only approved agents are used. The variant for contactless examination uses one of the two disinfection areas for taking samples. A glass partition with integrated glove system and a corresponding sample lock are used for contactless transfer.

Another special variant of containers enables the disinfection of packages and objects. Here, too, the disinfection room is set up as a lock. A revolving conveyor belt transports parcels and objects through the disinfection lock and disinfects them within 30 – 60 seconds.

The mobile disinfection container for a contactless examination.

The areas of application for containers are diverse. The mobile disinfection container can disinfect a large number of people externally in a short time and is in demand in places where sick, immunocompromised or otherwise endangered people meet frequently and thus there is a high risk of infection which necessitates barrier measures. containers can therefore be placed wherever people need to be disinfected quickly and easily, provided the right disinfectant is used. Thanks to the integrated energy management system sun2safe, the containers can also be placed in remote regions of the world or in locations away from the power grid or unreliable power supply.

The mobile disinfection rooms are operated with renewable energy. The sun2safe energy management and solar energy storage solution from the meeco group serves this purpose. It is an energy management and storage system that is able to provide solar energy that is generated directly on the roof of the containers immediately, evenly and reliably and to store excess energy for later use.

Peter Kenkel GmbH and the meeco group combine their skills with container in a solution for social health. This created a disinfection room operated with renewable energy to contain a rapidly spreading virus pandemic that can be shipped and used worldwide without any problems.